High-efficiency standard electrode adopts standardized design and is widely applicable

Low noise during operation, strong stability, can effectively reduce energy consumption and save costs

The surface electrophoresis coating process of the whole machine is antirust and corrosion-resistant, and the product has a longer service life

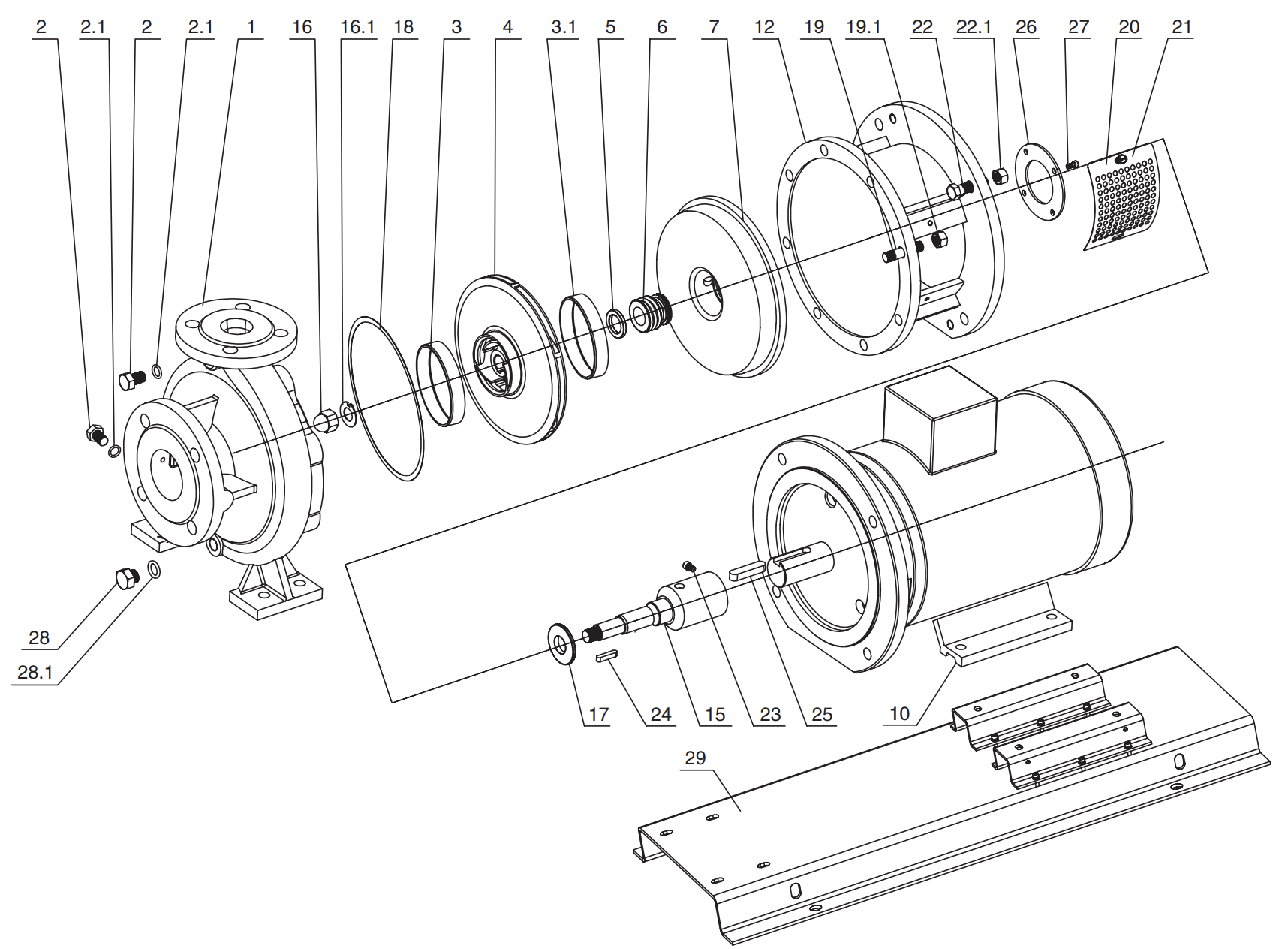

The motor and the pump shaft are rigidly connected, and the user does not need to adjust the shaft during use

Back-pull structure, can be repaired without disassembling the pipeline

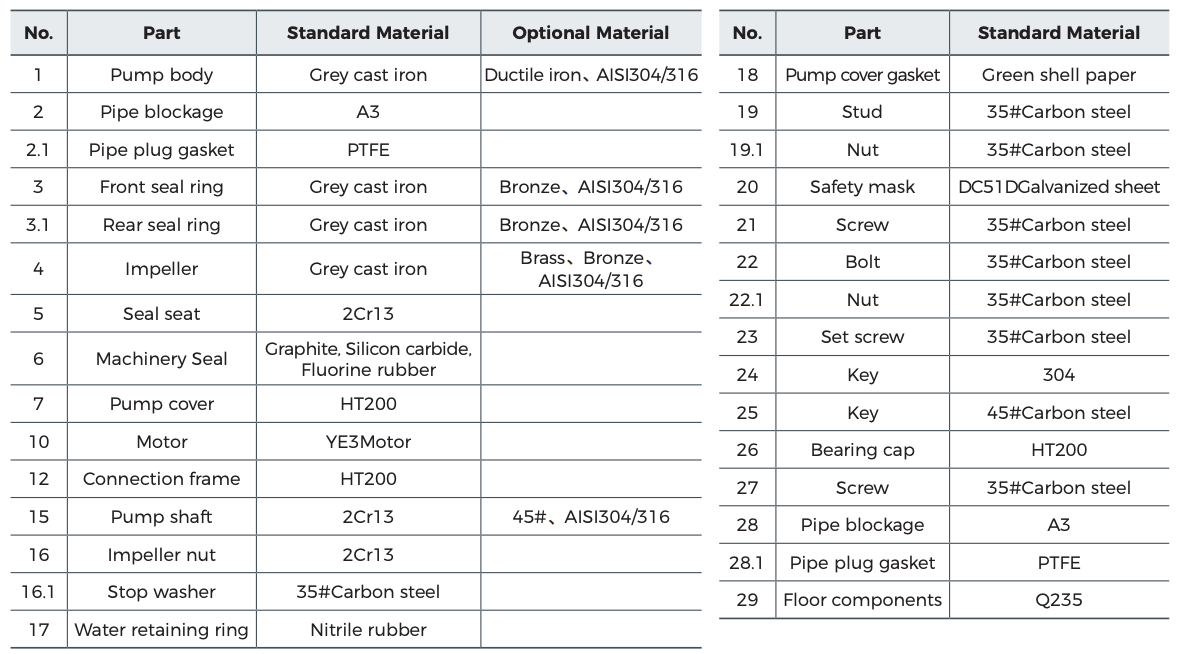

According to different usage requirements, provide various materials/types of pump bodies, impellers, and mechanical seals customized services